Research

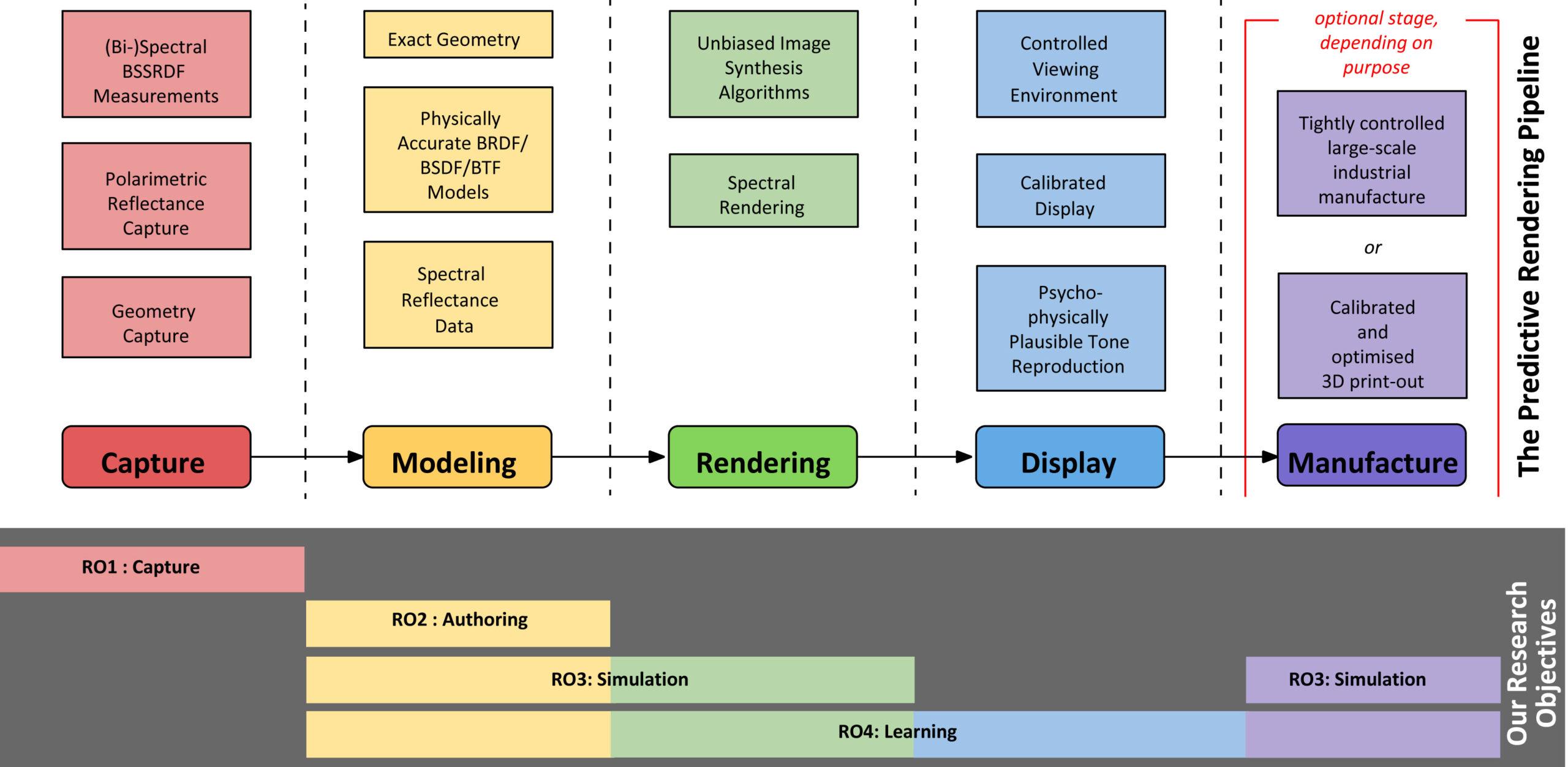

The global objective of our proposed research is to increase fidelity and reliability of predictive rendering technology, both with the goal of accurate on-screen output (which includes the ability to predict sensor readings, such as for autonomous car training), and with the goal of being able to predict manufacturing appearance within fine tolerances.

We concentrate our research plan on four broader research objectives, these are:

RO1 - Improved Capture

capture techniques provide input data for the modeling stage, and are of critical importance in predictive workflows. While capture technologies for some types of materials exist, others are still severely lacking: mainly because believable rendering workflows simply did not need such capabilities up to now, as artists would typically manually craft appearance to match expectations, and not use measurements.

RO2 - Improved Authoring

working with both capture data and highly realistic material models is in some cases radically different from standard workflows, and needs research before it reaches the same level of utility as normal workflows. Also, working with such input data constraints artists in some regards, so new techniques which enable efficient measurement-based creative processes are needed.

RO3 - Improved Simulation

this topic encompasses three of the five possible stages, as accurate simulations are needed in all of them, for various purposes. Simulations are used for modelling purposes, rendering simulates the propagation of light in a scene, and manufacturing techniques are being optimised via simulations of light interaction with the manufactured object.

RO4 - Improved Learning

here, we aim at two separate aspects of predictive rendering technology. The first is the use of predictive rendering results in machine learning settings, such as in the training of autonomous vehicles. The second is employing deep learning techniques for optimisation of the actual rendering pipeline, including capture, authoring and light transport simulation.

We partially treat manufacture, the fifth step of the predictive pipeline, as an implicit given, and do not work on this topic with all partners:

PGBS and IKEA produce their goods on an industrial level via fairly conventional means, and our concern in their case is solely with the predictive ability of their prototyping tools. But for other use cases, such as small-scale 3D printing via cutting edge polyjet colour 3D printers, we will actually conduct active research on optimisation of output appearance, and the enhancement of 3D printer capabilities to novel material classes.